Diagram of carburetor small engine – Embark on an in-depth exploration of the diagram of a carburetor small engine, a crucial component that governs the heart of your engine’s performance. This guide delves into its intricate workings, empowering you with a comprehensive understanding of its function, components, and maintenance.

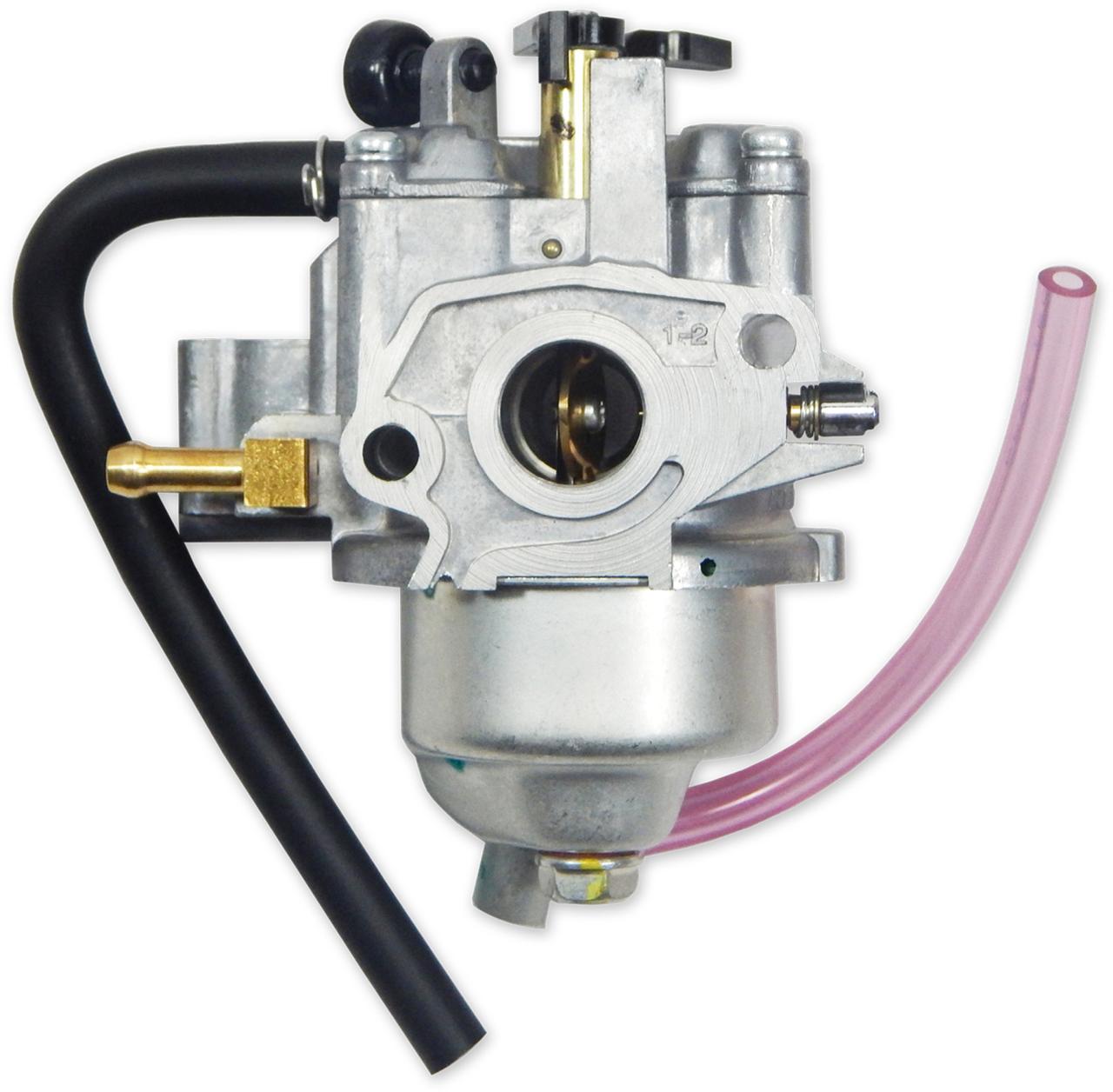

Our journey begins with an overview of the carburetor’s purpose and its fundamental role in regulating the air-fuel mixture. We’ll unveil the basic diagram of a carburetor, meticulously labeling its key components to provide a clear visual representation.

Overview of Carburetor in Small Engines

In small engines, the carburetor plays a crucial role in ensuring optimal engine performance. It is responsible for mixing air and fuel in the correct proportions to create a combustible mixture that powers the engine. The carburetor also regulates the flow of this mixture into the engine’s cylinders.

Carburetors come in various types, each designed to suit specific engine requirements. The most common types include the fixed-jet carburetor, the adjustable-jet carburetor, and the diaphragm carburetor.

Basic Diagram of a Carburetor

A basic carburetor consists of several key components, including the following:

- Fuel inlet: Where fuel enters the carburetor.

- Float chamber: Where fuel is stored at a constant level.

- Float: A device that regulates the fuel level in the float chamber.

- Venturi: A narrow section in the carburetor that increases air velocity, creating a low-pressure area that draws fuel from the float chamber.

- Throttle valve: A valve that controls the amount of air and fuel mixture entering the engine.

- Idle mixture screw: A screw that adjusts the fuel-to-air ratio at idle speed.

Components and Functions of a Carburetor

A carburetor is a crucial component in a small engine, responsible for mixing air and fuel in the correct proportion to ensure efficient combustion. It comprises several essential components, each playing a specific role in the fuel delivery process.

Fuel Bowl and Float

The fuel bowl acts as a reservoir for the fuel, maintaining a consistent level. The float, connected to a needle valve, floats on the fuel surface. As the fuel level drops, the float descends, opening the needle valve to allow more fuel to enter the bowl, replenishing the supply.

Throttle Valve

The throttle valve, controlled by the throttle linkage, regulates the amount of air flowing into the carburetor. By opening or closing the valve, the engine operator can control the engine speed and power output. When the throttle is open, more air is drawn in, resulting in a richer air-fuel mixture and increased power.

Conversely, closing the throttle reduces airflow, creating a leaner mixture and lowering engine power.

Venturi

The venturi is a narrow section in the carburetor’s throat. As air passes through the venturi, its velocity increases, creating a low-pressure area. This pressure difference draws fuel from the fuel bowl through a small orifice, known as the main jet.

The high-velocity air then atomizes the fuel into fine droplets, ensuring thorough mixing with the air.

Air-Fuel Mixture Adjustment

The air-fuel mixture is crucial for the optimal performance of a small engine. It directly affects the engine’s power output, fuel efficiency, and emissions.

Idle Mixture Screw Adjustment

The idle mixture screw controls the amount of fuel entering the engine at idle speed. Adjusting this screw allows you to fine-tune the engine’s idle stability and fuel consumption.

Main Jet Size Adjustment

The main jet controls the fuel flow at higher engine speeds. Selecting the appropriate jet size ensures that the engine receives the correct amount of fuel for optimal performance throughout the operating range.

Consequences of Incorrect Air-Fuel Mixture

- Lean Mixture:Too much air and not enough fuel, leading to engine overheating, detonation, and reduced power.

- Rich Mixture:Too much fuel and not enough air, resulting in incomplete combustion, increased fuel consumption, and spark plug fouling.

Troubleshooting Common Carburetor Issues

Carburetors, like any mechanical component, can experience issues that affect their performance. Understanding these common problems and their solutions can help you maintain your small engine’s carburetor and ensure optimal operation.

Flooding

Flooding occurs when excess fuel accumulates in the carburetor, causing it to run rich. Symptoms include difficulty starting, black smoke from the exhaust, and rough idling.

- Check the fuel level in the carburetor bowl. If it’s too high, adjust the float valve.

- Inspect the carburetor gasket for leaks. Replace it if necessary.

- Clean the carburetor jets to remove any debris that may be blocking fuel flow.

Hesitation, Diagram of carburetor small engine

Hesitation refers to a delay in engine response when you press the throttle. It’s often caused by a lean fuel mixture.

- Adjust the air-fuel mixture screw to enrich the mixture.

- Check the fuel filter for clogs. Replace it if necessary.

- Inspect the carburetor throttle linkage for binding or wear.

Surging

Surging is an intermittent increase and decrease in engine speed. It’s typically caused by a rich fuel mixture.

- Adjust the air-fuel mixture screw to lean out the mixture.

- Check the carburetor idle speed adjustment. It may need to be lowered.

- Inspect the carburetor diaphragm for tears or leaks.

Importance of Regular Carburetor Maintenance and Cleaning

Regular carburetor maintenance is crucial to prevent these issues and ensure optimal performance. This includes cleaning the carburetor periodically to remove any accumulated dirt, debris, or varnish.

Advanced Carburetor Modifications: Diagram Of Carburetor Small Engine

Advanced carburetor modifications can enhance engine performance by optimizing fuel delivery and air-fuel mixture. These modifications include installing larger jets, modifying the venturi, and adjusting the float level.

Larger Jets

Larger jets allow more fuel to flow into the carburetor, resulting in a richer air-fuel mixture. This can improve power and torque, especially at higher RPMs. However, it can also lead to increased fuel consumption and emissions.

Venturi Modification

Modifying the venturi, the narrowest part of the carburetor throat, can alter the air velocity and fuel flow. A larger venturi allows more air to flow, which can improve power and efficiency. However, it can also reduce low-end torque.

Float Level Adjustment

Adjusting the float level ensures the correct fuel level in the carburetor bowl. A higher float level results in a richer mixture, while a lower float level results in a leaner mixture. Proper float level adjustment is crucial for optimal engine performance and fuel efficiency.

Safety Precautions and Guidelines

- Always wear safety gear, including gloves and eye protection.

- Disconnect the fuel line and battery before performing any modifications.

- Use proper tools and follow manufacturer’s instructions.

- Test the carburetor after modifications to ensure proper operation and adjust as necessary.

FAQs

What is the purpose of a carburetor in a small engine?

A carburetor is responsible for mixing air and fuel in the correct proportions to create a combustible mixture for the engine.

How does a carburetor maintain the proper fuel level?

The fuel bowl and float work together to maintain a constant fuel level in the carburetor.

What is the role of the throttle valve in a carburetor?

The throttle valve controls the amount of air entering the carburetor, which in turn affects the air-fuel mixture.